With sustainability demands on tech hardware supply chains increasing rapidly, many technology companies are seeking to understand how to align supplier performance with their own growing supply chain ESG commitments.

Building and optimizing relationships with suppliers will be key to driving better supply chain ESG performance, while providing companies the opportunity to improve supply chain resilience, efficiency and productivity, manage and reduce operational costs, minimize labor disruptions and create business value through increased market share and price premiums. According to equity research by Goldman Sachs, organizations that have implemented these approaches have experienced a 16% valuation premium over their competitors and 3% higher earnings before interest, taxes, depreciation, and amortization (EBITDA) compared to companies without such practices (14% vs. 11%).

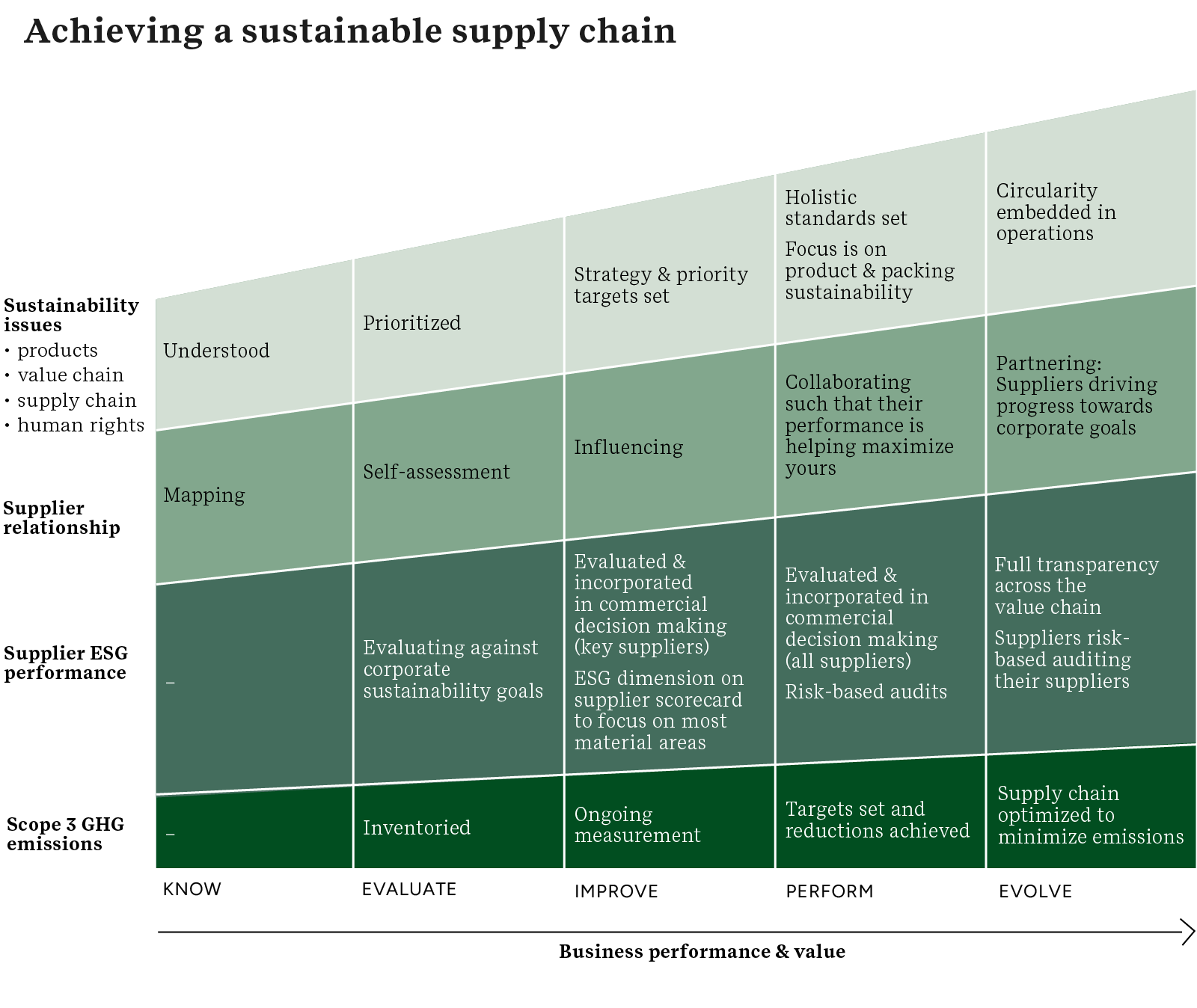

To achieve sustainability maturity in supply chains, companies can follow a five-stage process detailed below, starting from mapping and getting to know suppliers and evolving towards aligning ESG goals and processes across the entire value chain:

1. Know your suppliers: The initial step in this journey is gaining a comprehensive awareness of suppliers. In the rapidly evolving technology industry, understanding the intricacies of the supply chain is crucial for managing sustainability and business performance. Original equipment manufacturers’ (OEMs) relationships with contract manufacturers and final assemblers are often characterized by deep collaborative design and scheduling. However, the real challenge lies in managing the extended supply chain, beyond direct suppliers.

The technology industry faces heightened risks in these extended tiers. Unlike the direct relationships with primary suppliers, visibility and control over secondary and tertiary suppliers diminish significantly. This lack of transparency and oversight exposes tech companies to various risks, including environmental, social, and regulatory non-compliance, which can have far-reaching consequences on their operations and reputation.

To mitigate these risks, organizations such as IBM have extended their focus beyond the immediate circle of direct suppliers. This involves comprehensively mapping the entire supply chain, identifying key players at each tier and understanding their specific sustainability challenges. In taking this approach, IBM reports 95% greater efficiency in handling global supply chain challenges.

2. Evaluate your suppliers: The influence of tech giants can be profound in the value chain. By setting stringent sustainability criteria and expecting their suppliers to adhere to these standards, they can initiate a ripple effect permeating the entire supply chain. Evaluating suppliers, especially those beyond the first tier, is crucial. It enables technology companies to gain insights into their suppliers' business practices, transparency and vulnerabilities.

To make this a reality, tech companies must encourage their suppliers to conduct thorough supplier assessments based on ESG criteria, selected based on prioritizing material issues within the tech company’s value chain and developing comprehensive emissions inventories. The goal is to ensure that every tier of the supply chain is not just aware of the company’s ESG goals but is actively working towards achieving them.

Hewlett Packard has focused on embedding high levels of sustainability in its product design and operations. The company aims to improve the energy performance of its product portfolio by 30 times compared to 2015 levels by 2025. HP has set a goal to reduce its manufacturing-related supply chain emissions by 15% by 2025, focusing on engaging suppliers to set science-based targets for their operations.

3. Improve supplier performance: In sustainable supply chains, the technology industry stands out for its unique approach to collaboration, driven by rapid innovation and digital transformation. Integrated digital tools and platforms are revolutionizing supply chain collaboration in the tech sector, enabling enhanced communication, efficient data sharing and real-time monitoring of supply chain activities. This digitalization streamlines operations and fosters a more responsive and efficient supply chain network.

Tech companies that facilitate a more collaborative relationship with their suppliers are better able to provide constructive feedback that improves supplier performance. This, in turn, will enhance transparency, circularity and position in the market. To reach this level of collaboration, technology companies should regularly conduct 3rd party audits of key suppliers at all levels of the supply chain to minimize risk, increase transparency and ensure compliance.

While the audit itself is an evaluation against ESG criteria, it creates an opportunity for capability building, enabling the suppliers to improve ESG performance over time. Many tech companies are also investing in training and skills building within their supply chains to accelerate the transition to better ESG performance.

Verizon has been proactive in promoting sustainability among its suppliers. The company's management of supplier relationships includes regular monitoring and improvement initiatives to ensure compliance with ethical, environmental and social standards. Such initiatives often involve detailed assessments, audits, and continuous engagement with suppliers to foster a culture of sustainability and responsibility.

4. Perform against aligned goals: In the technology industry, comprehensive supply chain management is increasingly recognized as crucial for aligning suppliers with corporate ESG targets. However, the responsibility of suppliers and OEMs goes beyond mere compliance - it involves a deeper collaboration on material issues and ESG criteria, fostering a culture of shared responsibility and sustainable growth.

Implementing a comprehensive risk assessment framework is essential for making informed sourcing decisions. This framework should encompass various factors, including environmental impact, labor practices and regulatory compliance. California legislation, SB 253 and SB 261, mandating companies to disclose their GHG emissions and climate-related financial risks, highlights the importance of risk frameworks.

Preparing for the European Union’s Corporate Sustainability Reporting Directive (CSRD), Dell Technologies has developed a strategy encompassing impact areas, such as climate action, circular economy, inclusive workforce, trust and digital inclusion. Dell has set nine key goals for 2030, demonstrating a commitment to ESG through their operational model and governance process. The company is conducting a double-materiality assessment to include environmental and social impact assessments, reflecting the expansion of internal functions involved in the process. This approach is essential in meeting the demands of regulations such as the CSRD, which requires detailed disclosure on sustainability issues, risks, and opportunities, including quantitative metrics and objectives.

5. Evolve towards business transformation: To truly excel and meet the evolving challenges and opportunities of today's market, tech companies must demonstrate a long-term commitment to monitoring and collaborating across all tiers of their supply chains. This involves engaging with suppliers and driving progress towards ambitious sustainability goals, including reducing scope 3 emissions and water usage, increasing circularity and adhering to stringent disclosure and reporting standards.

To reach this advanced level of supply chain maturity, technology firms must actively engage in comprehensive risk analysis and transparent management practices across their entire supply network. This includes investing significantly in their suppliers, informed by thorough mapping and risk assessments.

Developing sustainability maturity in supply chains will be essential for companies to radically evolve their business models and capture new market opportunities. Key to this evolution is the use of in-depth scenario planning, using technology to rapidly assess ESG and operational trade-offs, which will enable companies to meet more challenging objectives like achieving circularity in their operations.

Supplier relationships need to be informed by a good governance model for supplier management. By utilizing mapping, engagement, monitoring and planning tools, companies can create an agile supply chain that is better equipped to deal with geopolitical uncertainty and changing supply and demand dynamics while also managing ESG risks and opportunities.

Author contacts

Ed Struzik – Partner, Supply Chain, Ed.Struzik@erm.com

Justin Goldston – Partner, Supply Chain, Justin.Goldston@erm.com

Lee Read – Partner, Engineer, Lee.Read@erm.com